The aim of a solid board converter is to sell boxes to his customers. He purchases his solid board in sheets or in rolls from the paper mill. He then converts them to high-value-added boxes.

The different kinds of boxes.

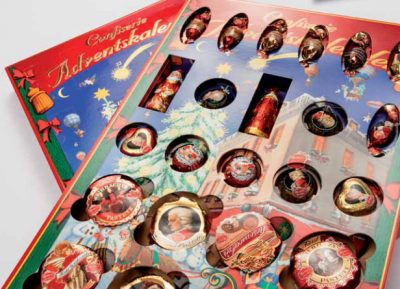

For example, the solid board converters work for the industries of food-processing, pharmaceutical laboratories, capital goods, wines and spirits, marketing services. This leads to a very wide product range, where the appearance of the final product is very important.

The box may comply with the ECMA standards, or it may be a customer’s specific box that has undergone an extensive CAD design.

Among the main box categories, following are a few examples:

- Straight flap boxes

- Reverse tuck-end boxes

- Auto-bottom boxes with tuck-end

- Trays with lock

- Display boxes with tuck-in flaps

- Pillow packs with end flap completely covered

- … and many others!

Manufacture of packaging.

The solid board sheets successively get through a number of converting machines, in order to produce the packaging expected by the customer:

- Printing: offset printing machine with coating units.

- Die-cutting: flat-bed die-cutting machine with blanking tool, and braille tool optionally integrated to the die-cutting plate.

- The folder-gluer: to fold and glue the boxes. Optional rotary braille tool.

- The strapping unit.

Storage and logistics.

A good stock management by batch and location is an essential management component for the business of a converter. The logistics, allowing for better delivery rounds, is also a key factor.

Volume Software’s answer to the needs of solid board converters: VoluPack ERP.

VoluPack information system is specifically targeted at solid board converters.

Our solution for solid board converters: VoluPack ERP

Credits photos : Winners Pro Carton / ECMA Award 2014